ABLE® Able® Safety Sleeve (Cut-Resistant Sleeve)

Some items of this product are available in our stock. The delivery time for this product is immediately if it is in our stock. Otherwise it is approximately 30 - 45 day(s) from the order. The reliability of the estimation is good.

Detailed availability

Notify me when this product is in stock again

Reviews

| Overall rating | (4 reviews) |

Product description

Able® Safety Sleeve (Cut-Resistant Sleeve)

The Able® Safety Sleeve is primarily intended for professional use to protect the wearer from superficial injuries such as abrasions and cuts. The sleeve consists of two layers: an outer layer of Cutlon® cut-resistant knit fabric and an inner layer of 8mm thick foam. The Able® Safety Sleeve is classified as a Category II personal protective equipment (PPE) product and is CE-marked. It is designed and manufactured in Finland, and the Cutlon® knit fabric is also made in Finland.

The ABLE Safety Sleeve is an innovative protective product designed especially for personnel who face physical challenges in their work, such as hitting, scratching, and biting. It has proven especially useful in early childhood education, kindergartens, schools, special care units, autism spectrum and developmental disability services, and adolescent psychiatric wards. Private individuals have also found the product valuable when caring for challenging children and youth.

Developed in collaboration with our customers, the ABLE Safety Sleeve is a high-quality protective product made entirely from Finnish materials. The outer cut-resistant fabric comes from the Finnish company OR Knitwear, ensuring both durability and comfort.

The sleeve’s outer material is Cutlon®, known for its cut resistance and durability. Beneath the knit, the foam layer wraps around the forearm to cushion trauma from impacts. Cut protection starts above the knuckles and extends past the elbow to the mid-upper arm, offering comprehensive coverage.

The sleeve has a flexible structure that ensures a snug fit, staying in place even in demanding situations. The cuff includes a practical thumb hole that enhances both fit and comfort. Please note that sleeves are always sold in pairs to ensure full protection.

One of the key advantages of the ABLE Safety Sleeve is its easy maintenance. Thanks to the manufacturing materials, the sleeve is machine washable at 60°C, making it easy to keep clean and ready for use.

The ABLE Safety Sleeve is committed to offering both protection and comfort in one product. It is designed to meet the demanding needs of the field and is an excellent choice for ensuring your safety.

Important Note on Safety

Complete protection cannot be achieved with the safety sleeve alone. Workplace safety also depends on the user’s proactive actions, behavior before and during an incident, and the nature of the threat. The severity of a physical attack depends on the attacker’s physical characteristics (e.g., build and strength) as well as psychological factors such as motivation, knowledge, and skill. Likewise, the defender’s own attributes affect the ability to respond, the risk of injury, and the experience of pain.

Effective protection against physical aggression requires not only protective gear but also proper training and regular practice.

Product Details

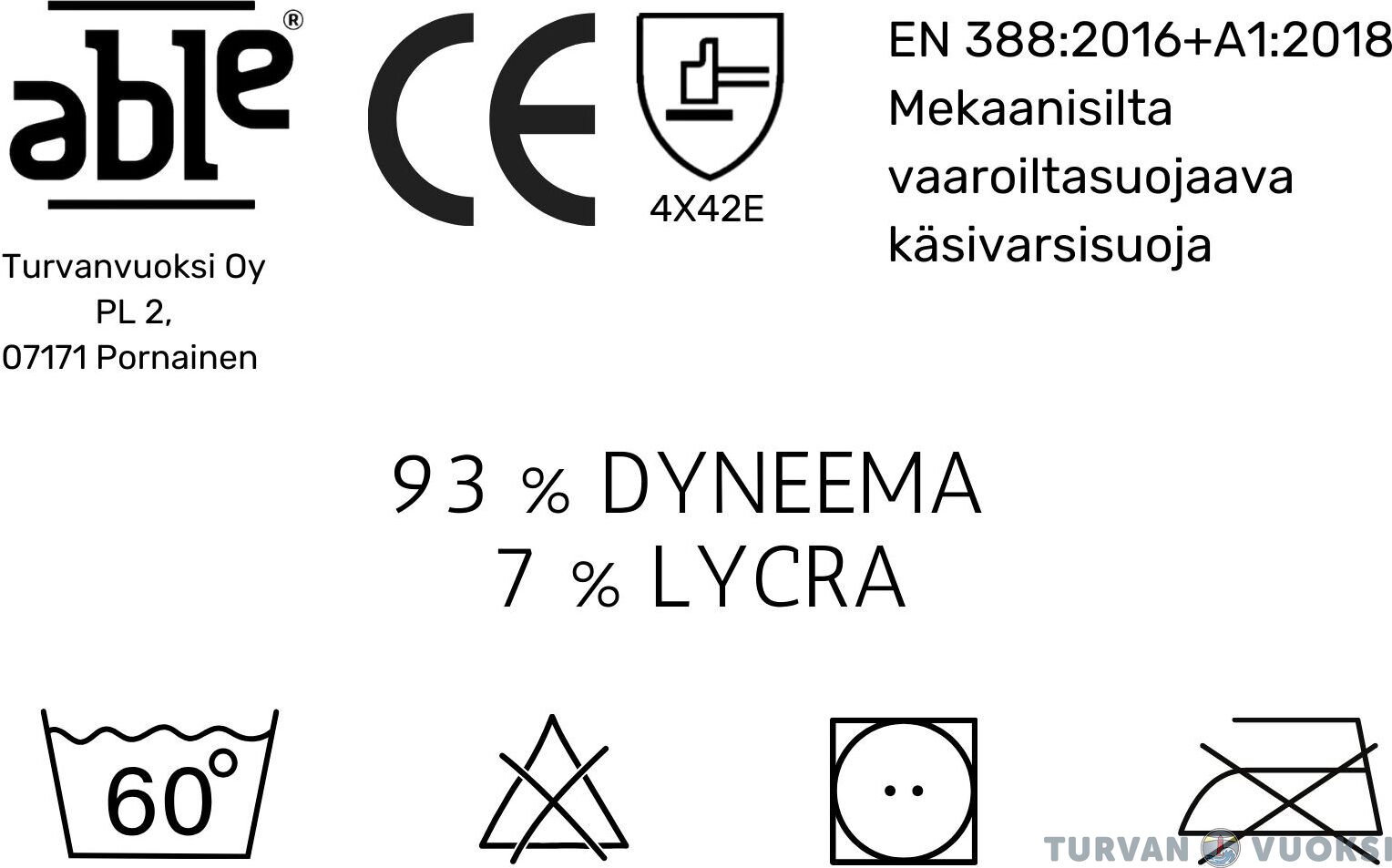

Able® Safety Sleeve meets the following standards: EN ISO 21420:2020 and EN 388:2016+A1:2018. It has been type-examined and certified by SGS Fimko Oy and is classified as a Category II PPE.

EU TYPE-EXAMINATION CERTIFICATE

Regulation (EU) 2016/425, MODULE B

0598/PPE/24/3101

EN 388:2016+A1:2018

The sleeve complies with all EN 388 levels:

4X42E (abrasion 4, blade cut X, tear 4, puncture 2, TDM cut resistance level E).

CE-marked. Classified as Category II PPE (protective clothing and gloves against cuts).

Protection level meanings:

Abrasion resistance levels 1–4 (best: 4)

Blade cut resistance levels 1–5 (best: 5)

Tear resistance levels 1–4 (best: 4)

Puncture resistance levels 1–4 (best: 4)

ISO cut resistance (TDM test): 6 levels from A to F (cut force 2–30 N).

“0” means the glove does not meet the minimum level for that specific hazard.

“X” means the glove was not tested or the test method is not suitable for the glove material.

The outer layer of the Able® Safety Sleeve is made of Cutlon® knit. Cutlon® is the world’s thinnest and most flexible cut-resistant knit! It combines comfort and extreme cut protection with easy maintenance. Cutlon® has been tested in certified laboratories according to the EN 388 standard. The material consists of 93% Dyneema and 7% Lycra.

Cutlon®’s excellence lies in the combination of polyethylene and elastane yarns. It is extremely durable, thin, flexible, and highly cut-resistant. Thanks to the polyethylene fibers, Cutlon® does not absorb moisture and transfers heat away from the skin—ensuring superior protection and the best comfort among cut-resistant knits.

Product Warranty

Able® Safety Sleeves carry a one-year (12-month) warranty for material and/or manufacturing defects from the date of delivery. If a defect is detected or the sleeve becomes damaged during normal use, we will replace it with a new product.

Please send us via email:

● A photo or photos of the damaged area

● A brief written description of the situation in which the damage occurred

● Your contact information

Manufacturer:

Turvanvuoksi Oy

P.O. Box 2, 07171 Pornainen, Finland

Tel. +358 40 414 1841

Business ID: 2676060-6

Email: info@turvanvuoksi.com

Website: www.turvanvuoksi.com

SGS Fimko Oy, Takomotie 8, 00380 Helsinki, Notified Body No. 0598, has type-examined this personal protective equipment in accordance with Regulation (EU) 2016/425.

1. Q: What is the ABLE® Safety Sleeve and what is it made of? A: The ABLE® Safety Sleeve is a CE-marked Category II Personal Protective Equipment (PPE), designed and manufactured in Finland. It is a cut-resistant and padded arm protector consisting of two parts: the outer layer is Cutlon® cut-resistant knit fabric and the inner layer is 8 mm thick closed-cell foam.

2. Q: What are the official protection classifications for the ABLE® Safety Sleeve (EN 388)? A: The safety sleeve complies with the standard EN 388:2016+A1:2018, with a classification of 4X42E. This rating indicates excellent abrasion resistance (4) and tear resistance (4), as well as good cut protection (TDM Cut Level E).

3. Q: Who is the ABLE® Safety Sleeve primarily intended for? A: The safety sleeve is designed for professional use in challenging situations, particularly for professionals in the social and healthcare sectors and education and upbringing fields, to protect against biting, scratching, and the threat of cutting.

4. Q: What materials is the ABLE® Safety Sleeve's cut protection made from? A: The outermost cut-resistant material is Cutlon® knit fabric, described by the manufacturer as the world's thinnest and most flexible. Cutlon® consists of 93% Dyneema and 7% Lycra.

5. Q: How does the ABLE® Safety Sleeve differ from the ABLE® Safety Jacket? A: The main difference is the type of protection: the Safety Sleeve is explicitly cut-resistant (TDM Level E), while the ABLE® Safety Jacket focuses on mitigating blows, bites, and scratches without comparable cut resistance.

6. Q: How should the safety sleeve be worn correctly? A: The sleeve is pulled onto the arm, with the thumb placed through the opening in the cuff's ribbing. The sleeve must fit snugly on the hand to stay in place. The protector must not be used in situations where it could get caught in moving or rotating machine parts.

7. Q: Is the ABLE® Safety Sleeve sold individually or in pairs, and what is the price? A: The safety sleeves are always sold in pairs. The price is €139 per pair (VAT 0%). They are available in four different sizes: S, M, L, XL.

8. Q: What maintenance procedures does the ABLE® Safety Sleeve require? A: The safety sleeve is easy to keep clean. The recommended washing temperature is 60∘C. Highly alkaline substances, bleaches, and solvent-type detergents should be avoided during washing. The use of fabric softener is not recommended.

9. Q: Why is the safety sleeve padded? A: The 8 mm thick closed-cell foam inside the safety sleeve wraps around the forearm and is designed to enhance protection beyond the cut resistance. It absorbs the force of bites and impacts while providing comfort.

10. Q: What is the warranty period for the ABLE® Safety Sleeve? A: The product has a one-year (12 months) material and/or manufacturing defect warranty from the date of delivery. The warranty covers defects and breakage during normal use.

11. Q: Who type-examined and certified the ABLE® Safety Sleeve? A: The safety sleeve has been type-examined and certified by SGS Fimko Oy (Notified Body No. 0598) in accordance with the EU Personal Protective Equipment Regulation (EU) 2016/425.

12. Q: What makes the ABLE® Safety Sleeve flexible and ergonomic? A: The safety sleeve is made from Cutlon® knit fabric (a blend containing Dyneema and Lycra), designed to be the world's thinnest and most flexible cut-resistant material. This ensures a snug fit and good mobility.

13. Q: In what situations should the use of the ABLE® Safety Sleeve be avoided? A: The safety sleeve must not be used in situations where it could get caught in moving or rotating machine parts, as this could lead to a dangerous situation.

14. Q: What benefits do ABLE® safety products offer to the employer? A: The safety garments are designed for demanding situations, and their use can reduce sick leave absences resulting from physical injuries to employees, such as blows, scratches, and bites.

15. Q: Can the ABLE® Safety Sleeve be tumble dried? A: Yes, the safety sleeve tolerates normal tumble drying (70−80∘C). However, it is recommended to reshape the product while it is still damp.

Warranty

12 month(s)

Return rate

0.00

Attachments

CommentsAdd a comment

Brand

Products that have often been purchased with this product

(+ VAT 25.5% = 259,60 €)

(+ VAT 25.5% = 363,95 €)